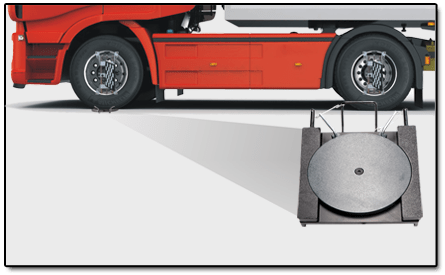

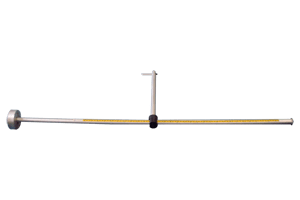

- Simultaneous Run out measurement up to 2 axles by driving rest of the axles through sequential

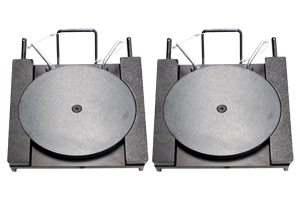

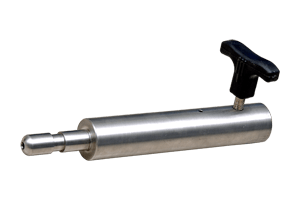

- No jack up of axle / No pushing mechanism for run out measurement

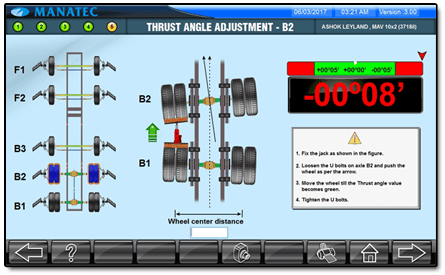

- Sequential Caster & Kingpin measurement of twin steer axles

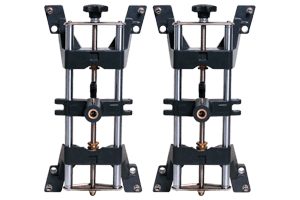

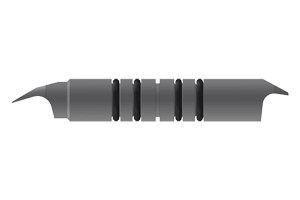

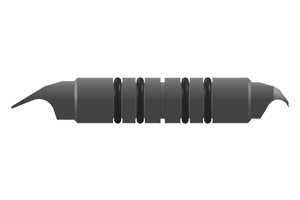

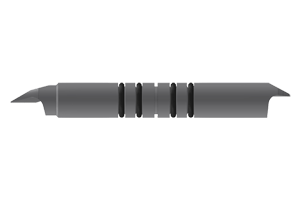

- No electronics on wheels

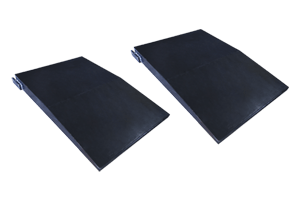

- Sequential alignment of Trailers up to 3 axles by reverse parking

- Data manager reports can be exported

- Power failure data protection (Resuming of current job in which stage the power failure happened)

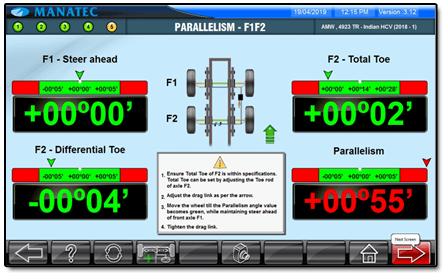

- Display of Toe in “deg. min"/“deg.”/ “mm"/“mm/M” / “inch” & other angles in “deg.”/“deg. min”/deg. fraction (1½°)

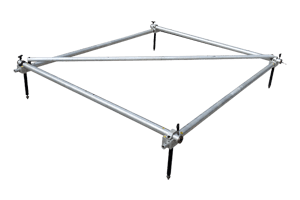

- Can be upgraded to Jumbo 3D Super 5A & 6A

- Camera coverage for 13 meters (Camera to last Target plate)

| Measurement Paraments | Range | Accuracy |

|---|---|---|

| Camber (Front / Rear) | ± 15° 00' | ± 00° 02' |

| Caster | ± 28° 00' | ± 00° 05' |

| Kingpin Inclination | ± 25° 00' | ± 00° 05' |

| Teo (Front/Rear) | ± 20° 00' | ± 00° 02' |

| Total Toe | ± 40° 00' | ± 00° 04' |

| Setback (Front / Rear ) | ± 25 mm | ± 2 mm |

| Scrub / Thrust Angle | ± 10° 00' | ± 00° 02' |

| Runout | ± 10° 00' | ± 00° 02' |

| Included Angle | ± 40° 00' | ± 00° 05' |

| Track width | Actual | ± 2 mm |

| Power Supply (wheel Aligner) | 230V, 50Hz / 110V AC, 60Hz | |

| Power | 250 W | Operating temperature | 0°-50°C |